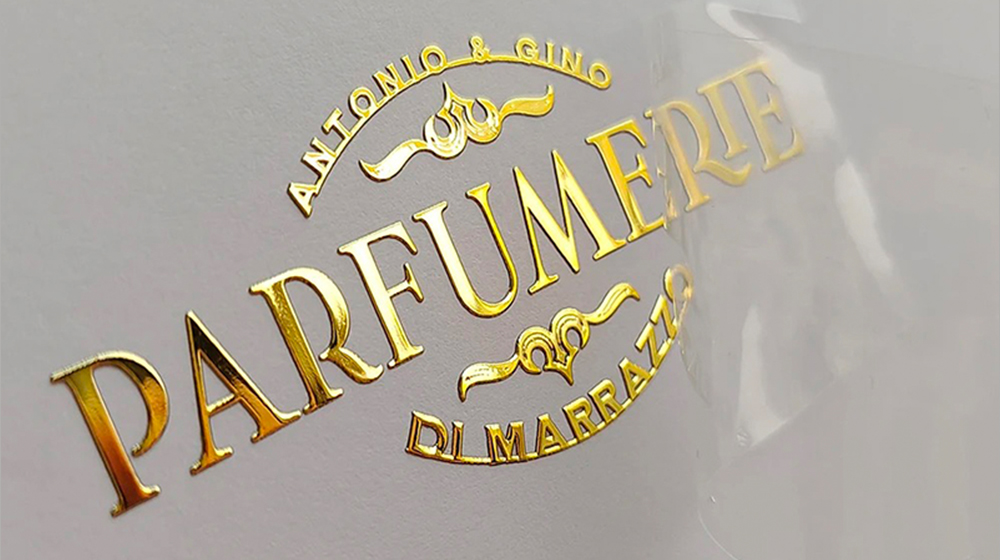

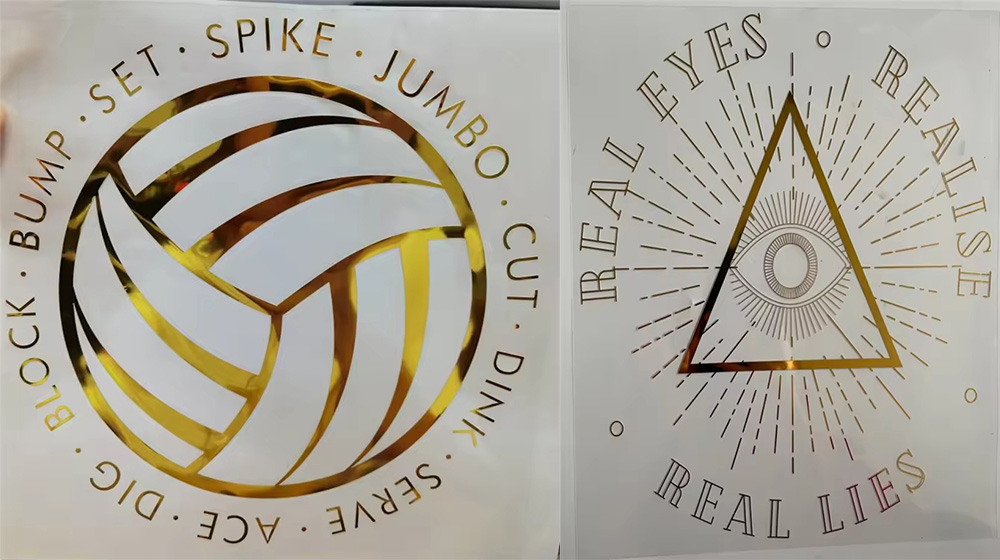

Our factory provides two kinds of gold transfer stickers ,one is gold foil uv dtf transfer stickers (Hot stamping transfer stickers ),the other one is gold nickle metallic transfer stickers.

We will introduce the difference between these two kinds of gold transfer stickers in detail.

No matter what kind of gold transfer sticker process you make, we can send your order within 48 hours. You can usually receive your order within 7 days.

Preparation Work

Before diving into the fascinating world of hot stamping, it’s essential to make thorough preparations. This includes not only understanding the basic principles and characteristics of hot stamping but also becoming familiar with the necessary equipment and materials, as well as mastering some basic operational skills. With these preparations in place, we can smoothly enter the realm of hot stamping and explore the secrets behind this technique.

Material Selection:

Hot stamping primarily uses standard types of paper as the base material.

Introduction to Metallic Foil:

Metallic foil, also known as hot stamping foil or gold foil paper, is produced by specialized manufacturers and comes in a variety of fixed colors such as red, black, blue, purple, green, and more. Within the same color family, different gloss finishes are also available—such as glossy gold, matte gold, light gold, and champagne gold.

Hot Stamping Plate Production:

Designers carefully engrave the desired text or images onto a metal plate. This metal plate is then used to press and transfer the design precisely onto the hot stamping material.

Detailed Steps

Next, let’s take a closer look at the detailed steps of the hot stamping process. During hot stamping, metallic foil (electrochemical aluminum) is placed between the paper and the heated metal stamping plate to ensure a clean, long-lasting stamped effect.

The process involves multiple steps, including the use of metallic foil, heating the metal plate, and transferring the design onto the paper. Below are the detailed steps:

Step 1:

Heat the hot stamping metal plate to approximately 100–150°C.

Step 2:

Apply pressure to bring the heated metal plate into contact with the metallic foil (electrochemical aluminum), pressing it onto the paper to begin the transfer process.

Step 3:

Ensure that the design or text on the hot stamping plate fully aligns and adheres to the surface of the paper.

Step 4:

Gently lift the hot stamping plate to separate it from the paper.

Step 5:

Under the residual heat of the metal plate, the colored layer of the metallic foil comes into contact with the design on the plate. This causes the foil’s colored layer to detach from its backing and adhere precisely to the paper surface.

Step 6:

Remove the excess metallic foil that has been left behind after the transfer is complete.

Step 7:

After the foil has been fully transferred and separated, clean off any remaining foil waste from the paper, revealing a flawless and refined hot stamped design.

The higher cost of hot stamping can be attributed to an innovative advancement in the printing industry—the “foil stamping before printing” technique. This method places extremely high demands on the quality of metallic foil (electrochemical aluminum). It requires not only precise stamping alignment and a smooth surface finish, but also consistent and balanced pressure to prevent issues such as bubbling or image blurring.

Additionally, factors like the indentation along the edges of the stamped design, the adhesion between the foil and the substrate, and the prevention of scratches or scuff marks must all be carefully controlled. Each of these details plays a critical role in achieving a flawless hot stamping result, contributing to the overall cost of the process.

The production process of CMYK UV DTF transfer stickers is much simpler. Just print UV ink on the white material and then cover it with transfer film. So the cost is much cheaper than Gold Foil Transfer Stickers.

Ultra-Thin Metal Transfer Stickers, also known as ultra-thin metal labels, die-cut metal self-adhesive nameplates, or custom enterprise logo metal label stickers, are high-end decorative branding solutions. So how are these ultra-thin metal transfer stickers made? Let’s explore the production process in detail.

These self-adhesive metal nameplates are primarily made from pure nickel, copper, and imported 3M adhesive. The thickness typically ranges from 0.04 mm to 0.15 mm, with 0.08 mm being the standard. Available in a variety of colors—including gold, silver, nickel, gunmetal, rose gold, red, blue, and even custom multicolor designs—these labels offer both versatility and premium appearance.

I. Production Process of Ultra-Thin Metal Labels

1. Photoresist Exposure (Plate Burning)

A stainless steel plate, which serves as the master mold for electroforming, is selected for its easy-release properties after plating. The plate is degreased and cleaned, then coated with a photoresist layer using a photopolymer (light-sensitive plating-resistant emulsion). After the design is exposed and developed, post-exposure treatment is applied to enhance the plating resistance of the photoresist.

2. Electroforming (Electroplating)

The developed stainless steel plate with the image is clamped securely into specialized fixtures and placed into a rapid electroforming nickel bath. The electroforming duration and current intensity depend on the surface area and desired thickness of the plated object.

3. Peeling (Separation)

Once electroforming is complete, the plated stainless steel plate is cleaned and dried. Then, a transfer film is used to peel off the electroformed text and patterns intact from the stainless steel surface.

4. Adhesive Application

There are two main methods:

Screen Printing Method: Pressure-sensitive adhesive is screen printed directly onto the back of the electroformed text and patterns. After drying, it is ready for application.

Transfer Method: Adhesive is first printed onto a transfer sheet and dried. Then the electroformed text and patterns (on the transfer film) are pressed onto the adhesive layer. Once firmly bonded, the adhesive is transferred to the back of the electroformed text and patterns.

This precise and advanced manufacturing process ensures that ultra-thin metal gold transfer stickers are durable, visually refined, and easy to apply, making them ideal for luxury branding on electronics, packaging, automotive products, and more.

We learned about the production process of these two gold transfer stickers and then summarized their differences.

Our client is in the wine business and has agents in many countries around the world. We provide them with stickers on wine bottles. The client is very satisfied.

The client has been in the wine business for generations and has his own vineyard.

We have a lot of retail customers, perfume customers, skin care product customers and health care customers. Our metal transfer stickers are very popular in the United States and Europe.

As long as you are willing to give us a chance to test on your products, we guarantee that you will continue to order our transfer stickers. Fast delivery and stable quality. We can also customize other embossed stickers.

Welcome to send us your stickers samples for customized .

We also can do rose red, blue , green ,purple ,white metal nickle stickers .

Metal transfer stickers do not fade or oxidize. They are painted with paint.

However, hot stamping film transfer stickers are prone to deformation over time, and they will also fade and oxidize. Only suitable for short-term use。

All of our items are customized ,so we have no price list for them.

We are always online for you ,welcome to email us or call us .

Because most of these stickers are small in size and light in weight, we use bubble bags of various sizes to pack them. This can well protect the stickers from damage during transportation.

For custom metal transfer sticker package ,all stickers will be separated into the individual sheets (17*30 cm ),and we do semi-cutting.

Option A : if we use DHL /Fedex / UPS to send our package ,it will take 3-7 work days to worldwide address .And you need to pay for your local tax fee or customs fee.We can not check the exactly cost from here. You need to check in your local customs first . Normally we will write a very low value in the commercial invoice ,so normally you just need to pay very less cost for the tax fee.

Because our package is cheap goods with light weight .We can write much lower value in the invoice .

Option B: We can provide DDP service by air ,it will take around 12 work days to your address ,but this cost is much cheaper than DHL / FEDEX/ UPS.And you do not need to pay any other your local customs fee and tariff cost .

A: No, these transfers are not microwave-safe due to their metallic components. Although they can withstand gentle handwashing and are water-resistant, they are not recommended for dishwasher use.

A: There is no difference—they are two names for the same product. Whether you call them UV DTF or Image Transfers, you’ll receive a high-quality decal with UV-cured, raised ink, no visible background, and a strong adhesive.

A: Yes, to ensure your transfer looks clean and prints correctly, we recommend:

Minimum line thickness: 5pt (approximately 1.8mm)

Smallest dot size: 60pt

Minimum letter height: 30pt

A: Yes, these stickers are not suitable for application on fabrics, silicone, or surfaces that repel adhesives (like powder-coated or glazed materials). This applies to both rigid and flexible surfaces.

A: Here’s a step-by-step guide:

Clean and dry the surface where the sticker will be applied.

Peel off the backing and carefully position the sticker. Firmly press all parts of the design to ensure good adhesion—especially around the edges.

Slowly peel back the transfer tape from one side. If part of the design lifts, press it back down and try peeling from a different edge to avoid tearing or misalignment.

For visual guidance, refer to our tutorial video available on our site (https://advertisingflagbanners.com/dtf-transfer-stickers/)

Our company was founded in 2008 and has been engaged in the production of custom flags and banners and other printed advertising products. The factory area has grown from 300 square meters at the beginning to 4500 square meters now.

Contact us right now to get more information, we will have people reply within 12 hours.

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.